Sonner double pull packaging f

01.09 2023

The production capacity of double pull packaging film is 8-10 tons per hour. Due to the roll design, about 5% of the uneven leftover material will be produced on both sides of the stretched film.

Under normal 24-hour operation, the equipment produces nearly 240 tons of packaging film every day, producing around 12 tons of leftover material, which is 360 tons in a month.

The film profit is only 2% -5%. When the production capacity reaches the upper limit, we can only start from raw materials and processes in order to increase profit. How to effectively tap into the value of leftover materials, truly achieve lean management and resource utilization? How can factories achieve closed-loop production within their own systems, creating sustainable economy?

The ideal solution is to recycle leftover materials, but the effectiveness of recycling has never reached the basic goal. The most anticipated thing for factory is direct online recycling, while most online recycling equipment cannot provide support for light and easily floating crushed materials. After researching market demand and expectations, we have launched the following solutions.

精益化管理

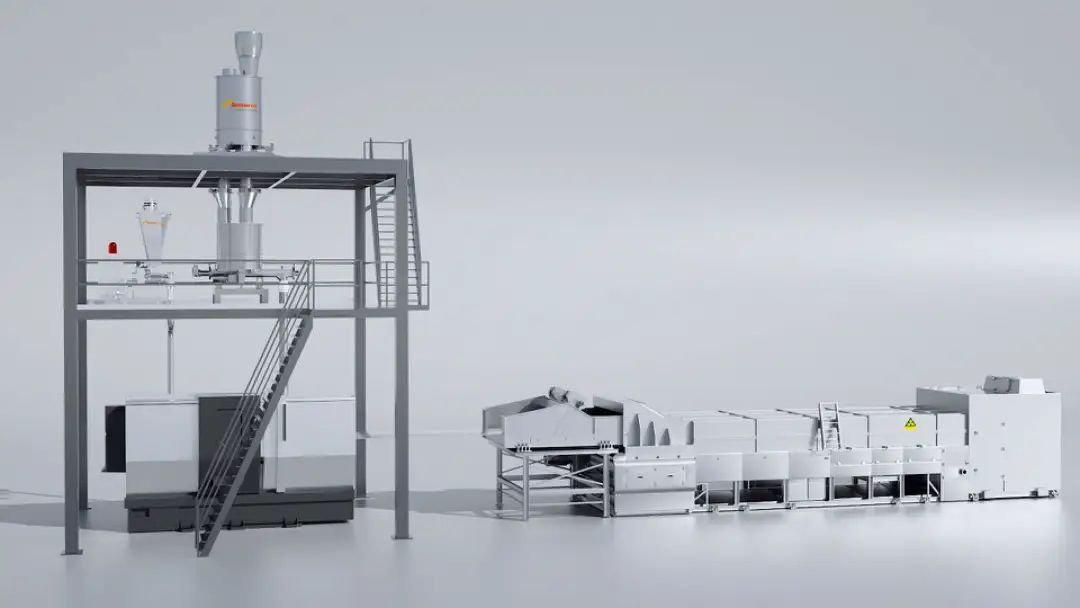

【Recycling process】

After the leftover material is crushed, it is directly recycled into a storage silo. After setting the addition ratio, it can enter the film production process through a dedicated loss-in-weight feeder for recycled materials.

The effective utilization of leftover materials saves raw material costs and frees up storage space in the factory. At the same time, online recycling solves the problem of offline time difference, which directly affects the profits of packaging film production enterprises, and the value of leftover materials is invisibly amplified.

计量稳定

Loss-in-weight

The equipment adopts the principle of loss-in-weight, monitors the raw material flow rate in real time, and continuously adjusts and optimizes it. The reduction degree is high, approaching the set value infinitely. It has the characteristics of constant torque and stable speed within a wide feeding range.

The dynamic weighing module receives weight signals in real time, measures, calculates, and transmits them, and the process is autonomous and controllable.

The raw materials have various forms such as particles, flakes, powders, liquids, etc. We will provide different refilling modes to solve the reliability and accuracy of refilling. The crushed leftover material is relatively light and prone to floating, making it easy to bridge in the silo. This is an important factor that many equipment cannot accurately dose the leftover material.

Considering the characteristics of the leftover material, we add an additional refilling silo in the feeding process to improve the feeding speed and prevent bridging of the storage silo.

At the same time, we design mixing devices in the refilling and dosing silos, and optimized the working speed of the horizontal bridge breaker to ensure that the raw materials do not undergo physical changes and can be fed smoothly.

The global amount of film scraps is huge, and recycling and reuse is a long task. With the promotion of national policies and the improvement of people's environmental awareness, reducing the use of raw materials and recycling production energy consumption has become a trend in industry development. Sonner always works with customers to fully tap into the value and potential of packaging film scraps, improve the plastic packaging production cycle, help enterprises achieve "zero waste" in film production, and promote the development of plastic circular economy.