S45 Single Screw

Loss-in-Weight Feeder

The lithium battery separator material is mainly composed of polyolefin separators, which have excellent mechanical properties, chemical stability, and cost-effectiveness. In addition to polyethylene and polypropylene, there are also polypropylene+ceramic coatings, polyethylene+ceramic coatings, as well as double-layer and three-layer materials based on polypropylene and polyethylene.

The requirements for diaphragm performance in downstream markets have gradually increased, and wet processes can better control the pore size, distribution, and porosity of diaphragms, so they are generally used to manufacture high-end thin films. However, domestic diaphragms started relatively late, and the technological maturity of domestic enterprises is not high. Many enterprises are also generally limited by technology and production equipment in the wet process.

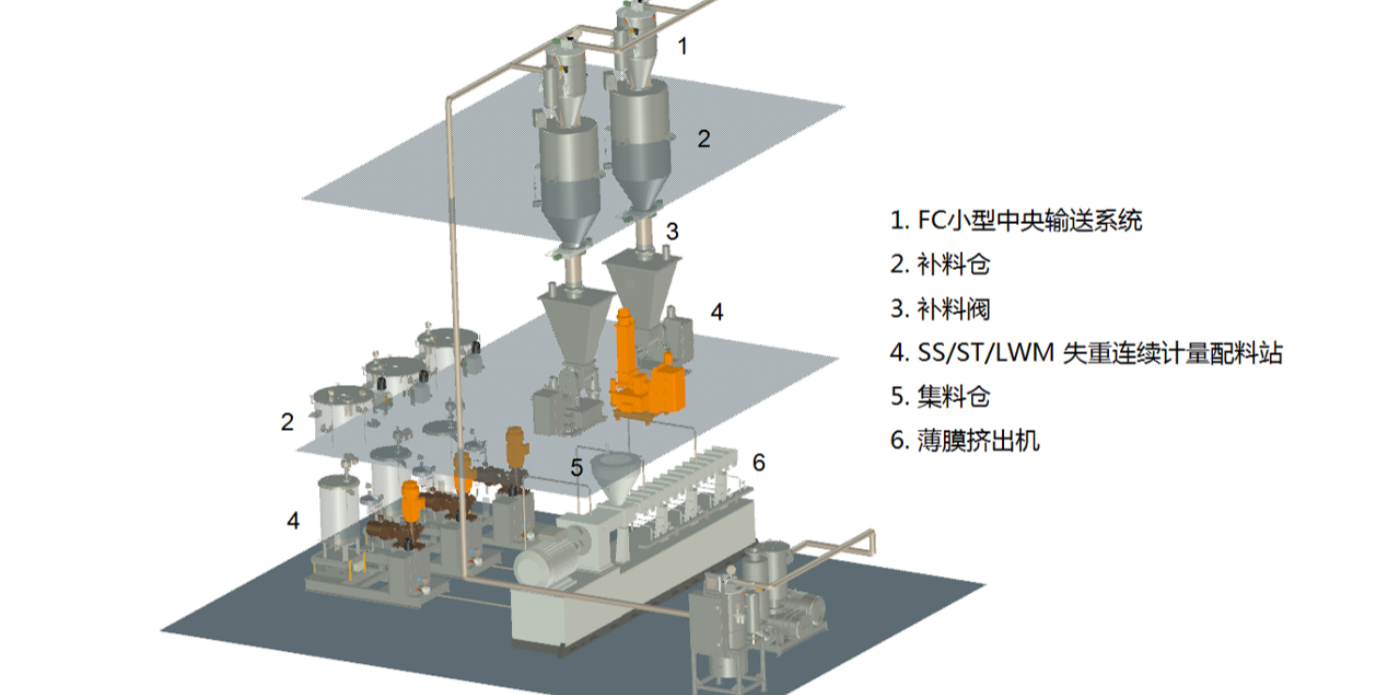

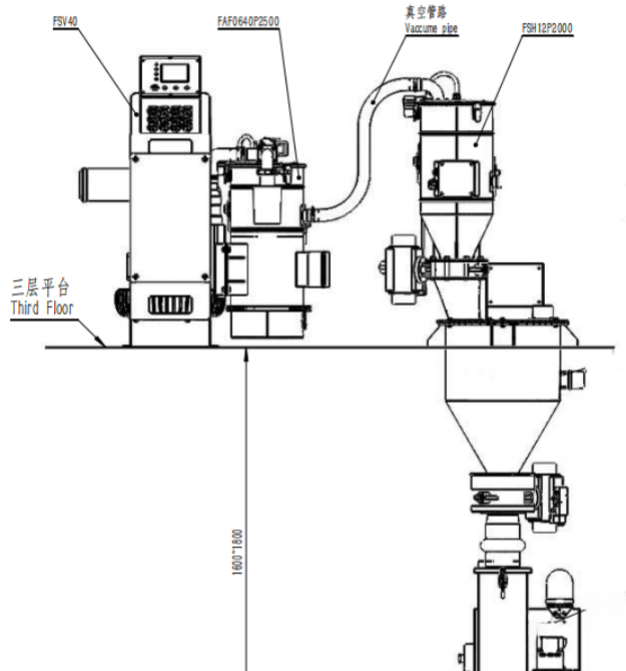

Sonner provides a standard loss-in-weight feeding mixing station for wet diaphragm process raw materials and additives. The mixing station includes particle material transportation, online weight loss continuous measurement of powdered and liquid raw material formulas, and synchronous mixing composition, making it an ideal and mature solution for extrusion film processing.

Dosing solution

FC conveyor system

Refilling silo

Refilling valve

S/T/LWM continuous loss-in-weight dosing system

Aggregate silo

Film extruder

Advantages of Sonner feeder

Recommended products