S45 Single Screw

Loss-in-Weight Feeder

In recent years, low smoke and halogen-free cable materials have received increasing attention in the industry. However, industry pets have also encountered some problems during the production process:

1. The process requires a variety of materials, complex and variable recipes, and difficult to control accuracy.

2. The components such as aluminum hydroxide and magnesium hydroxide in the recipe have high viscosity and are easy to bridge in the silo.

3. Most flame retardants are powder materials, which can easily cause dust pollution.

How can we achieve stable and accurate measurement in an environment filled with dust, complex recipes, and significant changes in material properties?

Sonner provides a complete set of recipe dosing solutions:

We provide components such as particle conveying, weight increasing batch mixer, weight reducing batch feeder, feeding bin, feeding valve, weight loss feeder, aggregate bin, etc.

We provide automatic and high-precision continuous or batch weighing, as well as feeding technology. We can design online and offline weighing systems for all types of materials in the recipe according to the customer's process, ensuring high efficiency, economy, and stable product quality.

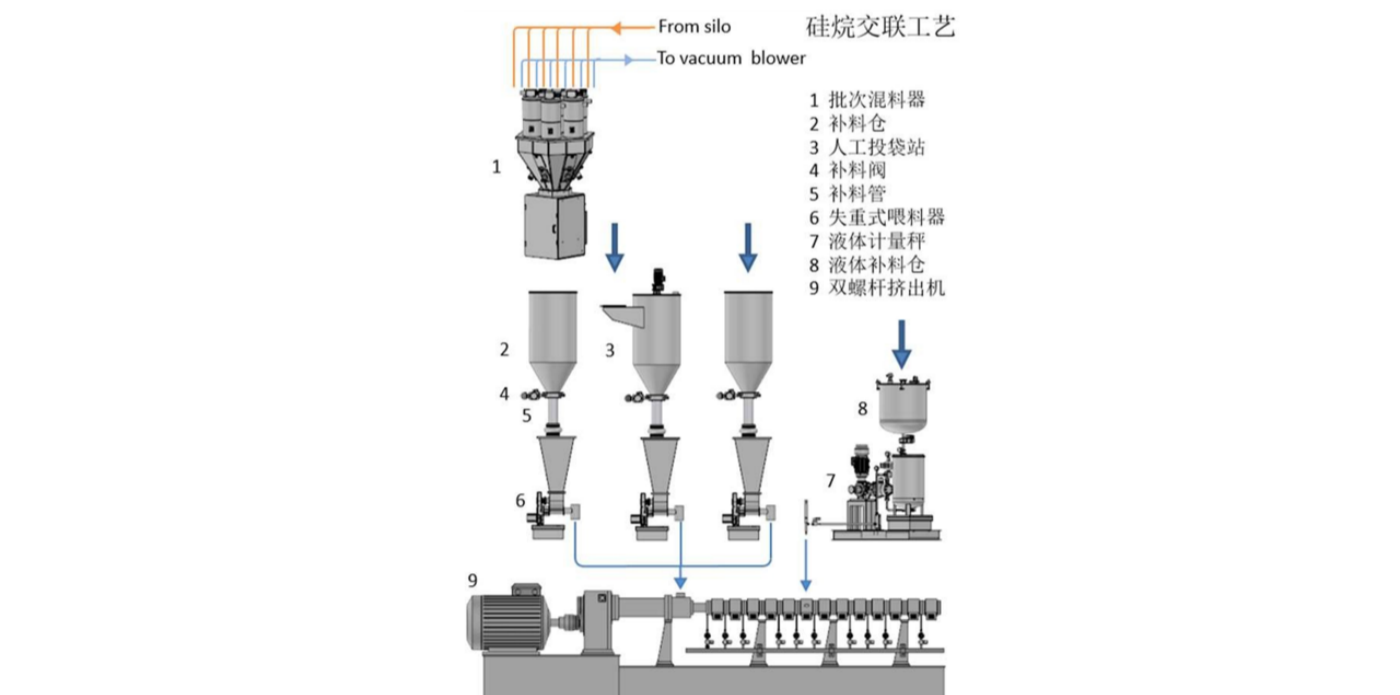

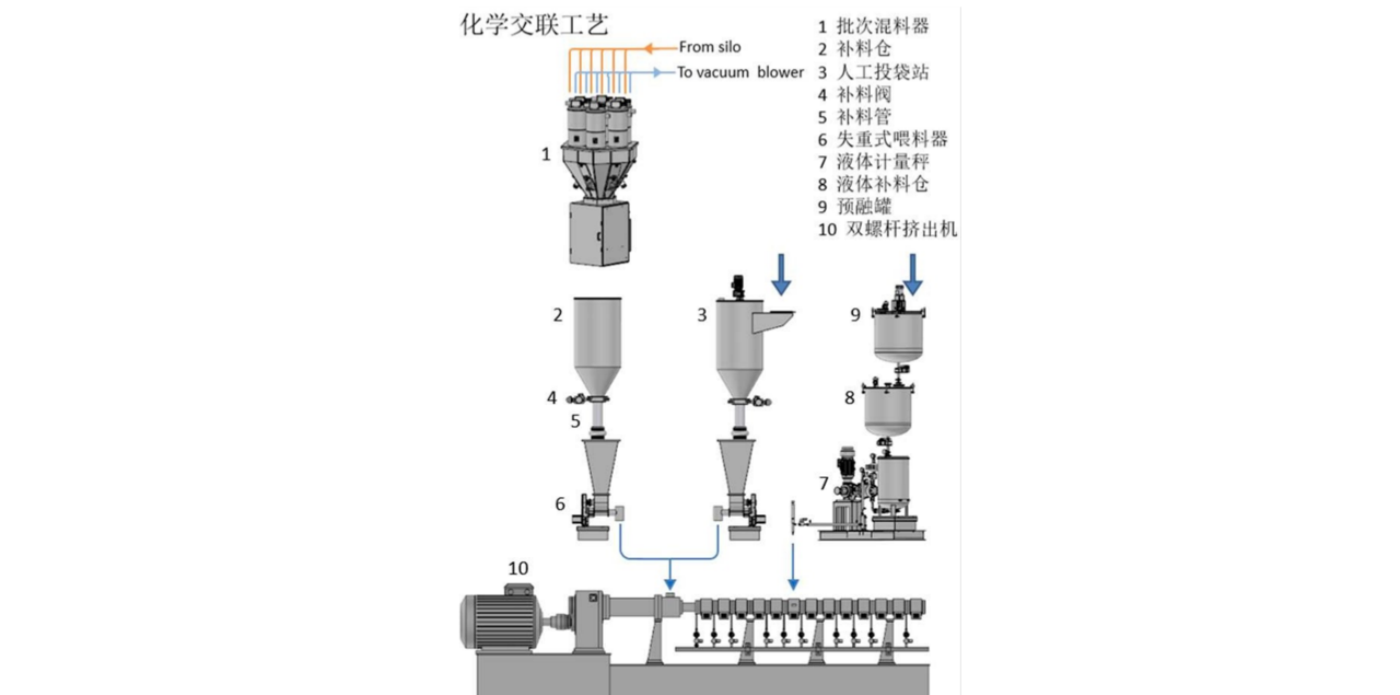

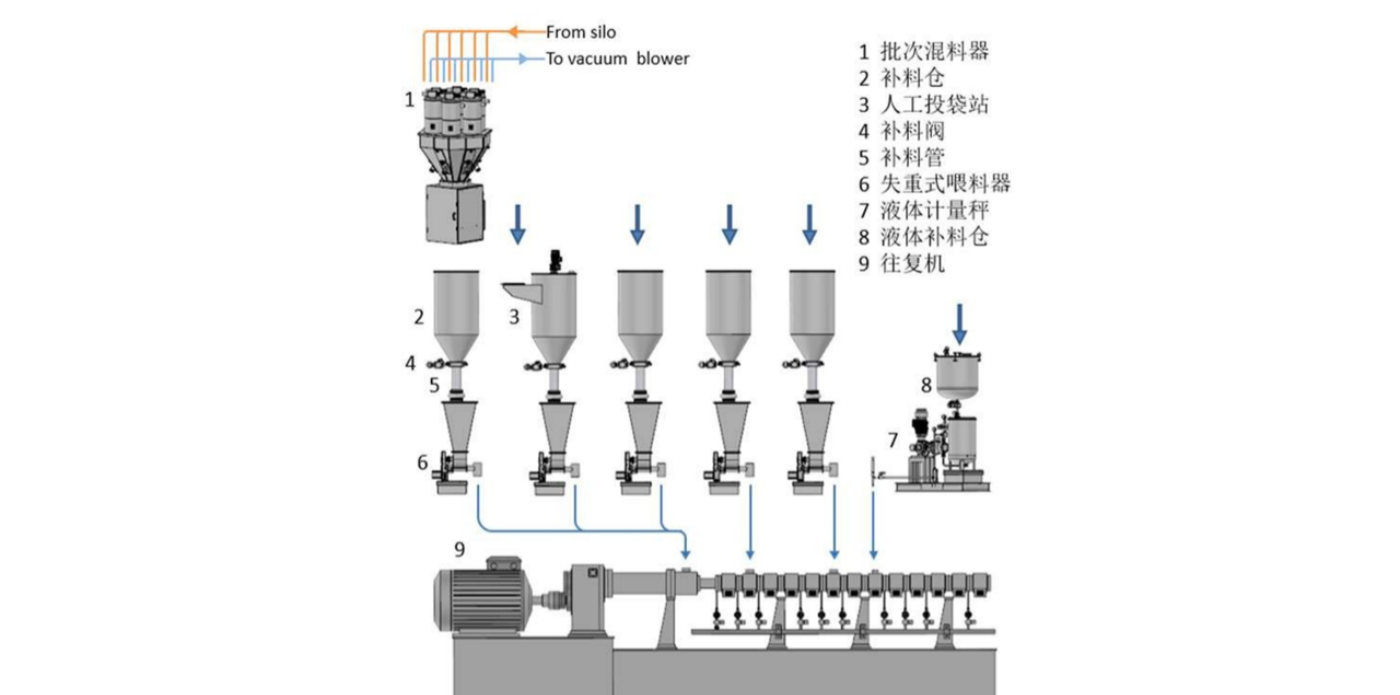

Typical applications

Dosing solution

Silane crosslinking

Chemical crosslinking

Halogen-free flame retardant

Batch mixer

Refilling silo

Manual bagging station

Refilling valve

Refilling tube

Loss-in-weight feeder

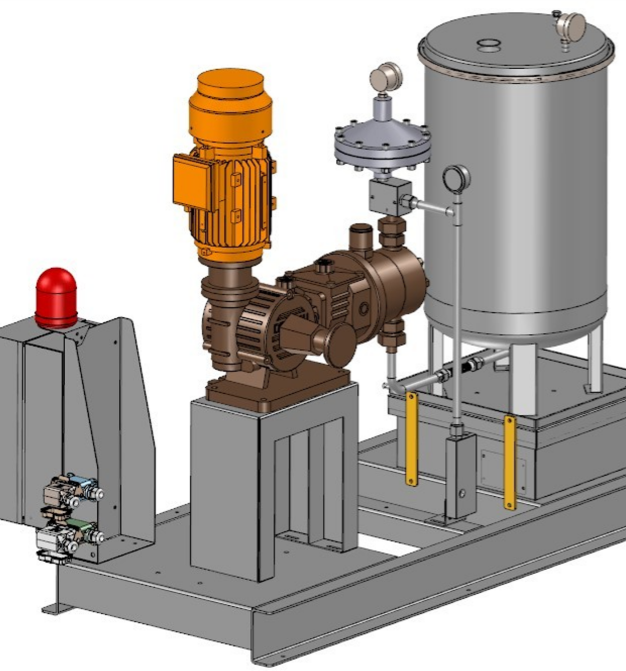

Liquid feeder

Liquid refilling silo

Reciprocating machine

Advantages of Sonner feeder

Recommended products