S45 Single Screw

Loss-in-Weight Feeder

The processing of color masterbatch has strict requirements for mixing technology and equipment: pigments and additives, basic resin components must be accurately measured, and then evenly dispersed and mixed into the basic resin through mixing systems such as twin-screw extruders and internal mixers.

At present, the production of color masterbatch, pigments and additives, and basic resin components in China are mostly achieved through manual pre mixing processes, which require manual feeding and metering. This process has a low degree of automation, poor accuracy of the formula, and significant environmental pollution. In recent years, the use of weight loss scales and separate addition processes in the production of black and white masterbatch has improved the accuracy and stability of the formula, while reducing environmental pollution.

Typical applications

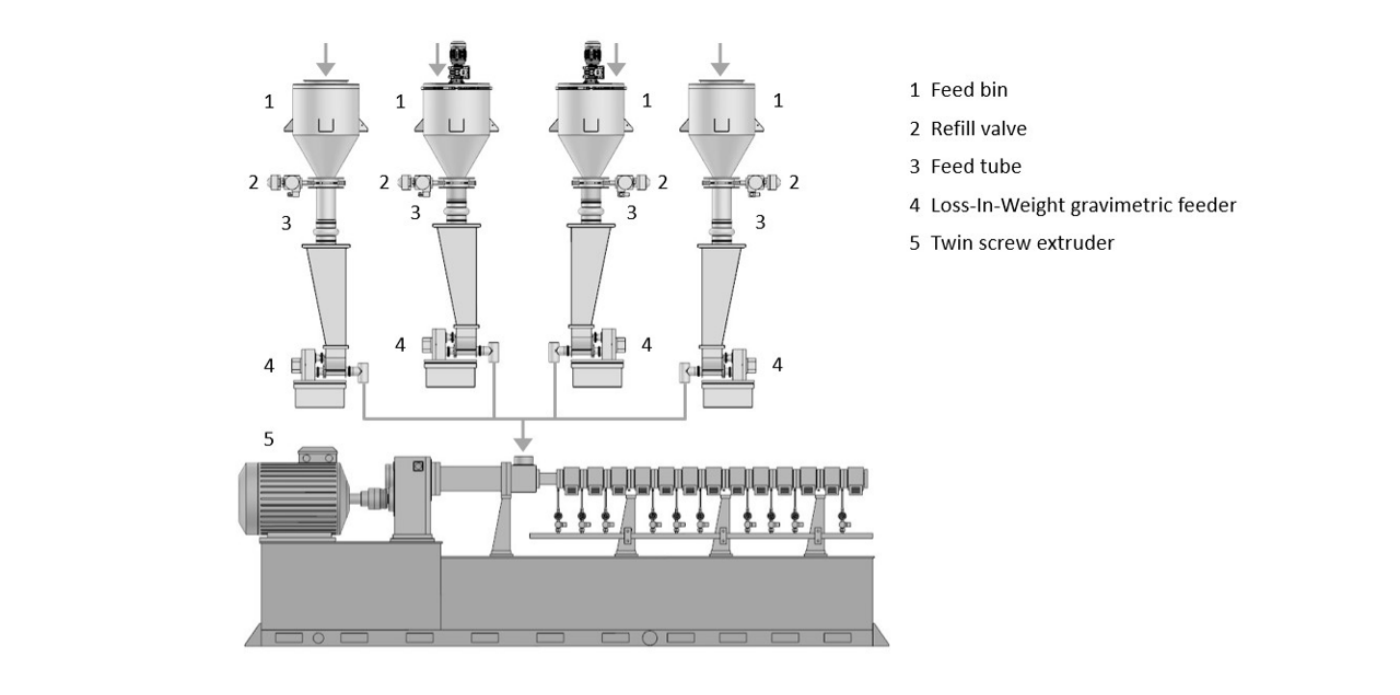

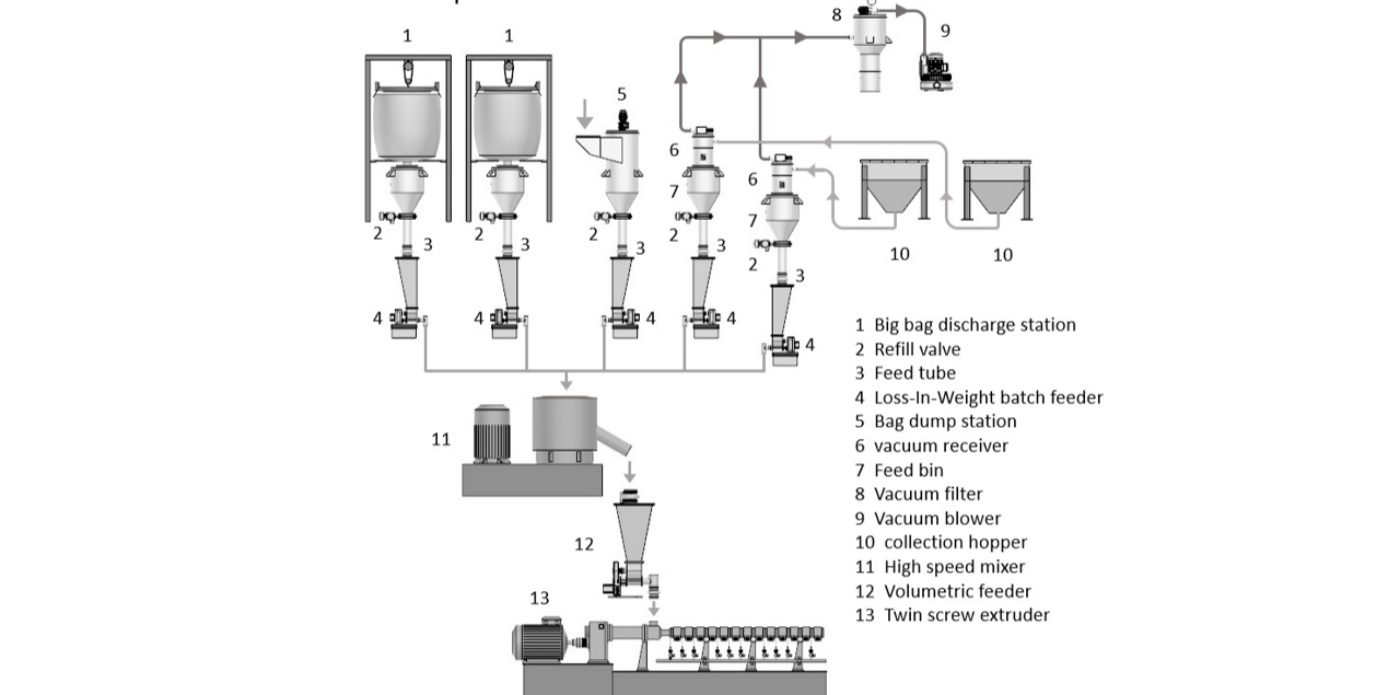

Dosing solution

Color-Matching

Premixed

Refilling bin

Refilling valve

Loss-in-weight feeder

Aggregate silo

Twin screw extruder or continuous mixer

Advantages of Sonner feeder

Recommended products