Weighing, transmission, and application,

Ensuring the stability of the feeder under high precision

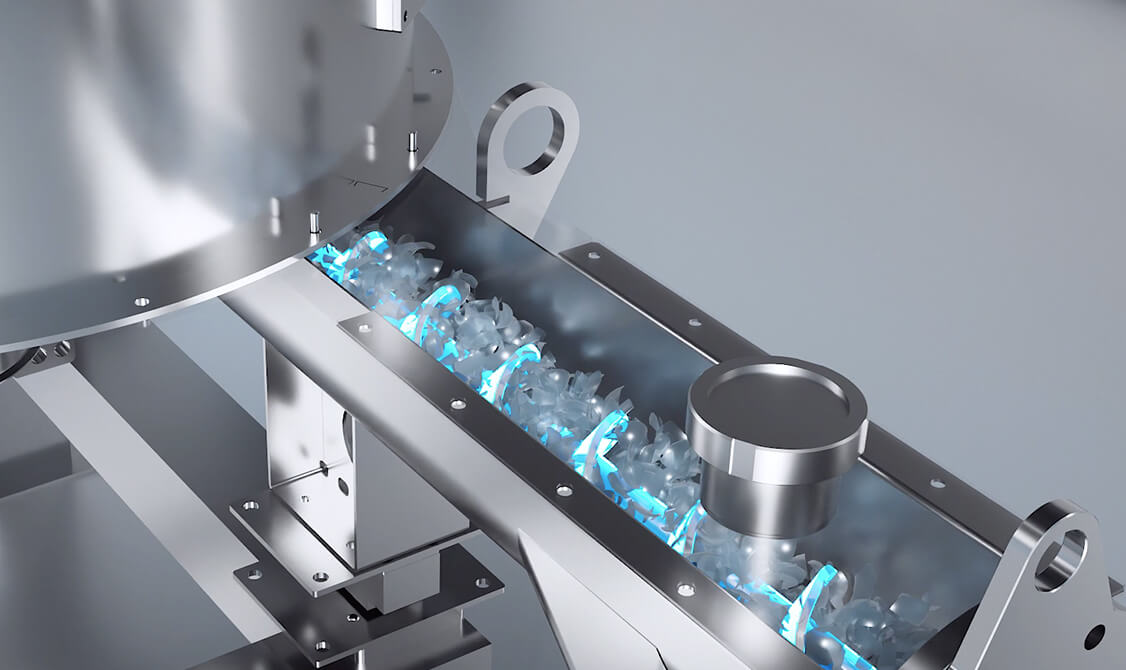

Comprehensive independent design:

Design and manufacturing of feeding screw

Design of brushless DC motors and gear transmission reducers

Development of weighing and measurement hardware and software

Since its establishment, Sonner has obtained 33 patents,

mainly related to dosing devices, conveying devices, filtering devices, etc.

1:400W

Integrated design of transmission device

The broad range of feeding also means that our products have the ability to be applied to more industries.

In the face of new industries, we have a fast technical response plan and a complete service process.

Quality Safety