Compact-M Multi-Station

Loss-in-Weight Feeder

In the film production process, the precise ratio feeding of various raw materials is the key part. Solar cell EVA packaging film is based on EVA, supplemented with several modifiers generally including EVA resin cross-linking agent, UV absorber, antioxidant (or anti- heat aging agent), UV stabilizer, plasticizer, tackifier etc.

Sonner provides a standard COMPACT loss-in-weight feeding and mixing workstation for the dosing of film raw materials with functional master batches, which is an ideal and mature solution for extrusion cast film processing and can well adapt to differentiation. The transition of materials is tracked to the data records of materials in real time.

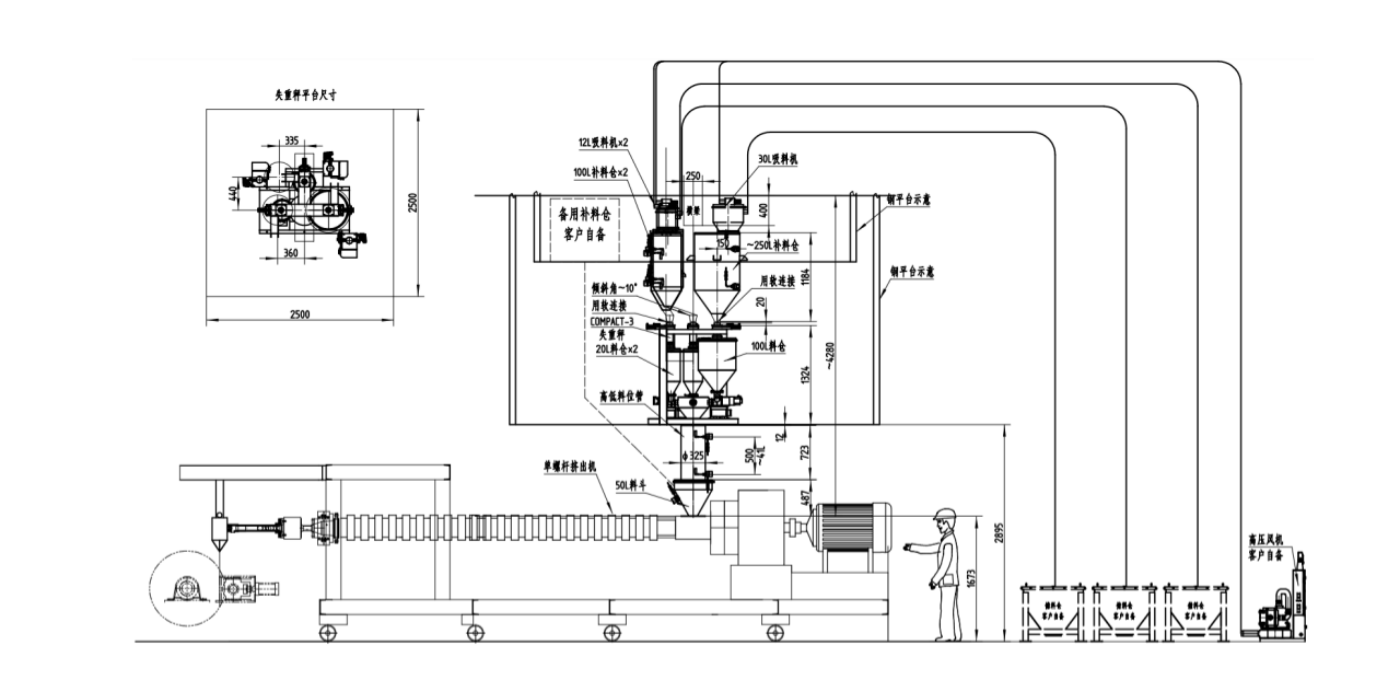

Dosing solution

FC small central conveying system

Refilling storage hopper

Feeding valve

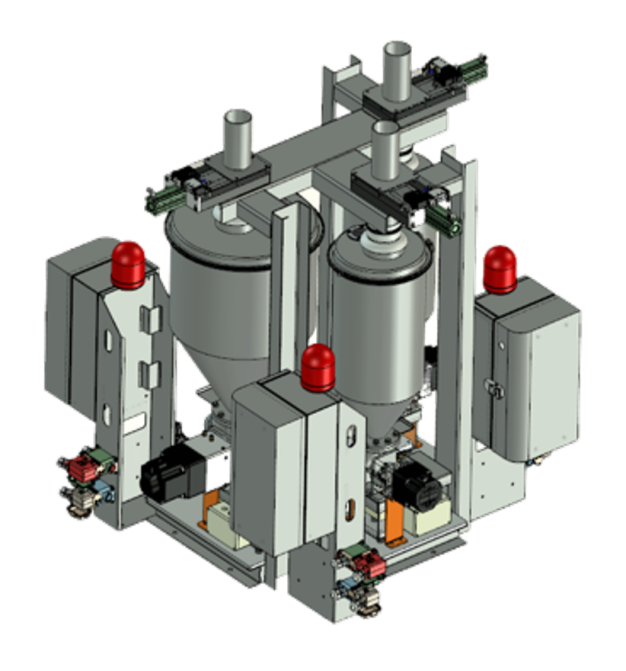

Compact-M Loss-in-weight mixing station

CCO yield tracker

Collection silo

Cast film extruder

Advantages of Sonner feeder

Recommended products