Sonner double pull packaging f

01.09 2023

Background

The lithium battery separator material is mainly composed of polyolefin separators, which have excellent mechanical properties, chemical stability, and cost-effectiveness. In addition to polyethylene, there are also polypropylene+ceramic coatings, polyethylene+ceramic coatings, as well as double-layer and three-layer materials based on polypropylene.

The requirements for diaphragm performance in downstream markets have gradually increased, and wet processes can better control the pore size, distribution, and porosity of diaphragms, so they are generally used to manufacture high-end thin films. However, domestic diaphragms started relatively late, and the technological maturity of domestic enterprises is not high. Many enterprises are also generally limited by technology and production equipment in the wet process.

Process

Online continuous loss-in-weight workstation

Extrusion cooling system

Synchronous biaxial stretching

Extraction

Horizontal stretching

Heat treatment

Rolling and slitting

Ingredients

1. 树脂:粉料,堆积密度0.5-0.6Kg/L;流动性一般

2. 树脂:粉料,堆积密度0.5-0.6Kg/L;流动性一般

3. 助剂:混合料,堆积密度0.4-0.5Kg/L;流动性一般

4. 白油:液体,堆积密度0.9-1.0Kg/L

Difficulty in measurement

1. Two types of resins need to be transported, and material replacement and cleaning are required during the metering process.

2. The amount of additives added is small, requiring high-precision measurement and weighing.

3. The raw material contains liquid and needs to be heated for measurement.

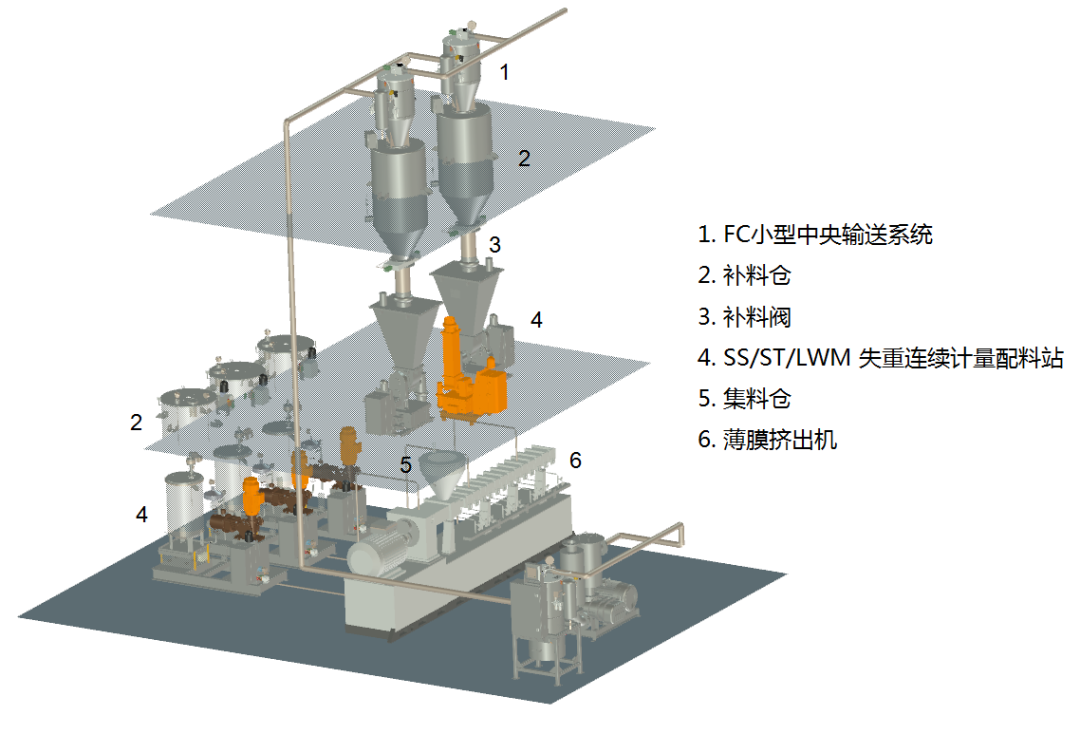

Sonner provides a standard loss-in-weight station for wet diaphragm process raw materials and additives. The station includes powder/particle material transportation, online continuous loss-in-weight measurement of powder and liquid raw materials. It is an ideal and mature solution for extrusion film processing.

Solution

Process solution

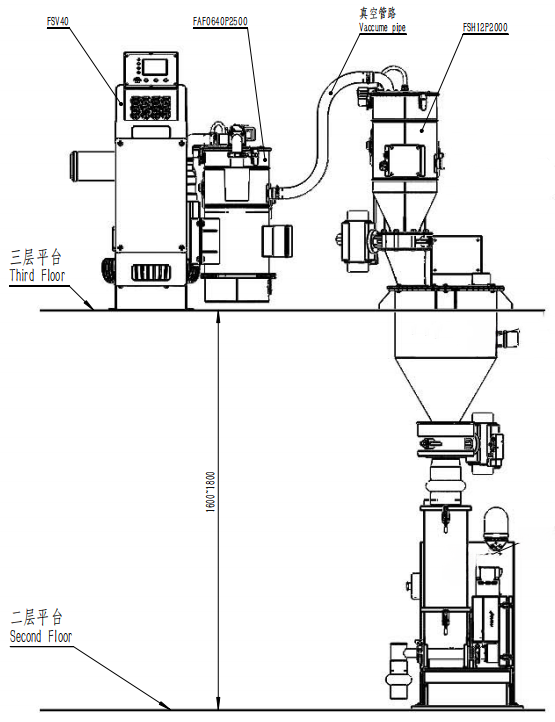

(线形工艺图)

配方中所有粉状原料经过FC输送系统进入失重配料站,提高了产线自动化水平

失重配料站采用高精度连续计量,小批量连续混料原理,提高了计量、混料精度,高度还原配方初始比例

助剂优化成独立小批量预混后进入助剂失重喂料器,相比于传统的与树脂或填充料大批量预混工艺,优化后的助剂配比质量更高

白油液体通过3台液体失重喂料器高精度连续计量后,直接通过喷枪注入挤出机筒体内,和其他原料同步混合,分布更均匀

Common equipment

Sonner technical feathers

(客户现场)

The feeding accuracy of the workstation reaches 0.25%, with continuous small batch synchronous mixing

Digital high-precision weighing technology, effective resolution reaches 1:4'000'000

Fast closed-loop speed control technology, flow rate (g/s) control adjustment frequency 500ms-1s, ensuring feeding accuracy of ± 0.25%

Mechanical vibration immunity technology, capable of intelligently distinguishing short-term impact from the surrounding environment

Excellent anti bridging performance, more precise and reliable flow control in the face of difficult to feed powder

Tool free quick disassembly design, simple and convenient cleaning and replacement

Good sealing performance, effectively reducing environmental pollution and dust overflow

Consult